Masisitimu ekutonhodza emvura ane nitrogen anoshandiswa zvakanyanya muindasitiri yesemiconductor & chips, kusanganisira maitiro e,

- Tekinoroji yeMolecular Beam Epitaxy (MBE)

- Kuedzwa kwechip mushure meCOB package

Zvigadzirwa Zvakabatana

EPITAXY YEMADHARA EMOLECULAR

Tekinoroji yeMolecular Beam Epitaxy (MBE) yakagadzirwa muma1950 kugadzira zvinhu zve semiconductor thin film uchishandisa tekinoroji ye vacuum evaporation. Nekuvandudzwa kwetekinoroji ye vacuum yakanyanya, kushandiswa kwetekinoroji kwakawedzerwa kumunda wesainzi ye semiconductor.

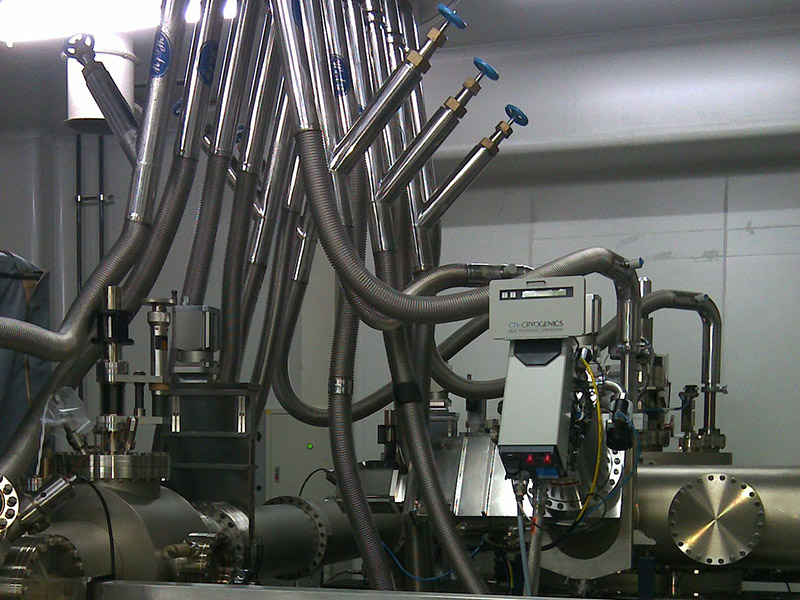

HL yakaona kudiwa kwe MBE liquid nitrogen cooling system, yakaronga technical backbone kuti ibudirire kugadzira MBE liquid nitrogen cooing system yakakosha ye MBE liquid nitrogen ye MBE tekinoroji uye seti yakazara ye vacuum insulated piping system, iyo yave ichishandiswa mumakambani mazhinji, mayunivhesiti nemasangano ekutsvagisa.

Matambudziko akajairika eindasitiri ye semiconductor & chips anosanganisira,

- Kumanikidzwa kweNitrogen yeLiquid muMidziyo yeTerminal (MBE). Dzivisa Kuwanda kweDzvinyiriro kubva kuMidziyo yeTerminal (MBE) Inokuvadza.

- Kudzora Kupinda Kwemvura Nekubuda Kwemvura Muzhinji

- Kupisa kweNitrogen yeLiquid muMidziyo yeTerminal

- Huwandu Hwakanaka hweCryogenic Gas Emissions

- (Otomatiki) Kuchinja Mitsetse Yepamusoro neYebazi

- Kugadziriswa kweDzvinyiriro (Kuderedza) uye Kugadzikana kweVIP

- Kuchenesa Kusvibiswa Kunogona Kuitika uye Zvisaririra zveAizi kubva muTangi

- Nguva Yokuzadza yeChishandiso Chemvura Chinoputika

- Kutonhodza mapaipi

- Kuramba Kwemvura muVIP System

- Kudzora Kurasikirwa kweNitrogen yeLiquid Panguva Yekusashanda kweSistimu

Pipe yeHL inonzi Vacuum Insulated Pipe (VIP) yakagadzirwa zvichienderana neASME B31.3 Pressure Piping code. Ruzivo rweinjiniya uye kugona kudzora mhando kuti ive nechokwadi chekuti fekitari yemutengi inoshanda uye inoshanda nemari.

MHINDURO

HL Cryogenic Equipment inopa vatengi Vacuum Insulated Piping System kuti ienderane nezvinodiwa nemamiriro eindasitiri ye semiconductor & chip:

1. Sisitimu Yekutarisira Hunhu: ASME B31.3 Kodhi Yemapaipi Ekudhinda.

2. Chinoparadzanisa Special Phase chine Multiple Cryogenic Liquid Inlet neOutlet chine automatic control function chinosangana nezvinodiwa zvekubuda kwegasi, nitrogen yemvura inodzokororwa uye tembiricha yenitrogen yemvura.

3. Dhizaini yakakwana uye yakakodzera yekubuda kwemhepo inoita kuti michina yemagetsi ishande zvakanaka mukati mehuwandu hwayo hwekumanikidzwa.

4. Gas-liquid Barrier inoiswa mupombi yeVI yakamira pamucheto wepombi yeVI. Gas-liquid Barrier inoshandisa musimboti wekuvharira gasi kudzivirira kupisa kubva kumucheto wepombi yeVI kuenda kuVI Piping, uye zvinobudirira kuderedza kurasikirwa kwe liquid nitrogen panguva yekusashanda kwesystem iyi uye nguva nenguva.

5.VI Pombi Dzinodzorwa neVacuum Insulated Valve (VIV) Series: Kusanganisira Vacuum Insulated (Pneumatic) Shut-off Valve, Vacuum Insulated Check Valve, Vacuum Insulated Regulating Valve nezvimwewo. Mhando dzakasiyana dzeVIV dzinogona kusanganiswa kuti dzitonge VIP sezvinodiwa. VIV yakabatanidzwa neVIP prefabrication mumugadziri, pasina Insulated treatment panzvimbo. Seal unit yeVIV inogona kutsiviwa zviri nyore. (HL inogamuchira cryogenic valve brand yakatarwa nevatengi, uye yobva yagadzira vacuum insulated valves neHL. Mamwe marudzi nemamodheru emavalvu angasakwanise kugadzirwa kuita vacuum insulated valves.)

6. Kuchena, kana paine zvimwe zvinodiwa pakuchena kwechubhu yemukati. Zvinokurudzirwa kuti vatengi vasarudze mapaipi esimbi isina tsvina eBA kana EP semapaipi emukati eVIP kuderedza kudonha kwesimbi isina tsvina.

7. Sefa yeVacuum Insulated: Bvisa tsvina inogona kusviba uye zvasara zvechando kubva mutangi.

8. Mushure memazuva mashoma kana kupfuura kuvharwa kana kugadziriswa, zvakakosha kuti utonhorese michina yeVI Piping neterminal usati waisa cryogenic liquid, kuitira kudzivirira ice slag mushure mekunge cryogenic liquid yapinda zvakananga muVI Piping neterminal equipment. Basa reprecooling rinofanira kufungwa nezvaro mukugadzirwa. Rinopa dziviriro iri nani kune michina yeterminal neVI Piping semavharuvhu.

9. Inokodzera zvese Dynamic uye Static Vacuum Insulated (Flexible) Piping System.

10. Sistimu yeMapaipi Ane Simba Anodzivirira Vacuum (Anochinjika): Inosanganisira mapombi eVI anochinjika uye/kana mapombi eVI, maJumper Hoses, Sistimu yeVacuum Insulated Valve, Phase Separators uye Dynamic Vacuum Pump System (kusanganisira mapombi evacuum, mavharuvhu esolenoid uye magauge evacuum nezvimwewo). Kureba kwepombi imwe chete yeVI inochinjika kunogona kugadziriswa zvichienderana nezvinodiwa nemushandisi.

11. Mhando dzakasiyana dzekubatanidza: Rudzi rweVacuum Bayonet Connection (VBC) uye Welded Connection zvinogona kusarudzwa. Rudzi rweVBC harudi kugadziriswa panzvimbo yacho.