Iyo yemvura nitrogen kutonhora masisitimu anoshandiswa zvakanyanya mu semiconductor & chip indasitiri, kusanganisira maitiro e,

- Iyo tekinoroji yeMolecular Beam Epitaxy (MBE)

- Iyo chip bvunzo mushure meCOB package

Related Products

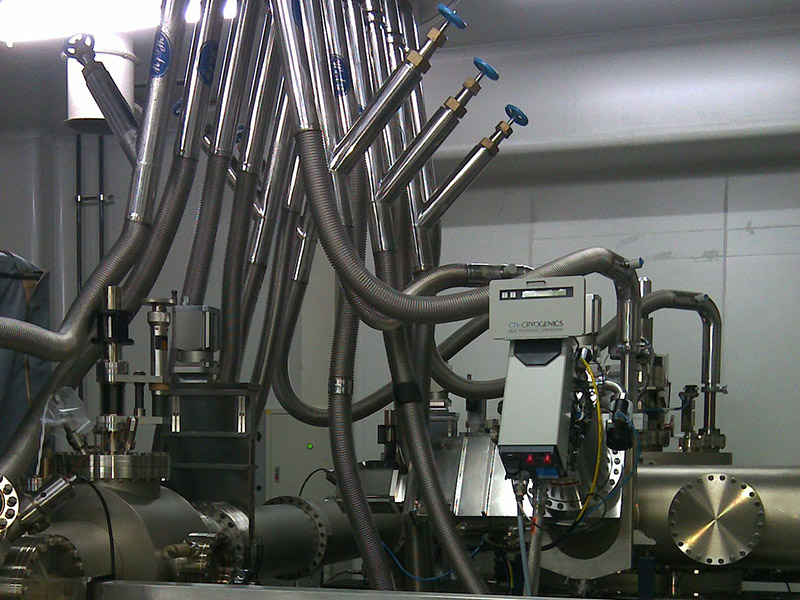

MOLECULAR BEAM EPITAXY

Tekinoroji yeMolecular Beam Epitaxy (MBE) yakagadziridzwa mu1950s kugadzirira semiconductor yakatetepa firimu zvinhu uchishandisa vacuum evaporation tekinoroji.Nekuvandudzwa kweyepamusoro-soro vacuum tekinoroji, kushandiswa kwetekinoroji kwakawedzerwa kumunda wesainzi semiconductor.

HL yaona kudiwa kweMBE liquid nitrogen kutonhora sisitimu, yakaronga tekinoroji musana kuti ubudirire kugadzira yakakosha MBE liquid nitrogen cooing system yeMBE tekinoroji uye seti yakakwana yevacuum insulated pombi system, iyo yakashandiswa mumabhizinesi mazhinji, mayunivhesiti uye masangano ekutsvagisa. .

Matambudziko akajairika eiyo semiconductor & chip indasitiri anosanganisira,

- Kudzvanywa kweLiquid Nitrogen muTeminari (MBE) Equipment.Dzivirira Kuwedzera Kudzvinyirira kubva Kukuvadza Terminal (MBE) Equipment.

- Multiple Cryogenic Liquid Inlet uye Outlet Controls

- Iyo Tembiricha yeLiquid Nitrogen muTeminari Equipment

- Nhamba Inonzwisisika yeCryogenic Gasi Emissions

- (Otomatiki) Kuchinjika kweMitsetse mikuru uye yeBazi

- Pressure Adjustment (Kuderedza) uye Kugadzikana kweVIP

- Kuchenesa Kubvisa Kusvibiswa Kungabvira uye Ice Yakasara kubva muTangi

- Kuzadza Nguva yeiyo Terminal Liquid Equipment

- Pipeline Precooling

- Liquid Resistance muVIP System

- Dzora Kurasika kweLiquid Nitrogen Panguva Yekurega Sevhisi yeSitimu

HL's Vacuum Insulated Pipe (VIP) yakavakirwa ASME B31.3 Pressure Piping kodhi seyero.Chiitiko cheinjiniya uye kugona kutonga kwemhando yekuona kugona uye kudhura-kunyatsoshanda kwechirimwa chemutengi.

SOLUTIONS

HL Cryogenic Equipment inopa vatengi neVacuum Insulated Piping System kuti isangane nezvinodiwa uye mamiriro eiyo semiconductor & chip indasitiri:

1.Quality Management System: ASME B31.3 Pressure Piping Code.

2.A Special Phase Separator ine Multiple Cryogenic Liquid Inlet uye Outlet ine automatic control function inosangana nezvinodiwa zvekubuda kwegasi, recycled liquid nitrogen uye tembiricha yenitrogen yemvura.

3.Adequate uye panguva yakakodzera yekupedza dhizaini inoita kuti zvigadziriso zvigadziriswe zvinogara zvinoshanda mukati meiyo yakagadzirirwa kumanikidza kukosha.

4.Gas-liquid Barrier inoiswa mu vertical VI pombi pamagumo eVI pipeline.Gas-liquid Barrier inoshandisa gasi seal musimboti kuvharira kupisa kubva kumagumo eVI pombi kupinda muVI Piping, uye zvinobudirira kuderedza kurasikirwa kwenitrogen yemvura panguva yekurega uye inopindirana sevhisi yehurongwa.

5.VI Piping Inodzorwa neThe Vacuum Insulated Valve (VIV) Series: Inosanganisira Vacuum Insulated (Pneumatic) Shut-off Valve, Vacuum Insulated Check Valve, Vacuum Insulated Regulating Valve etc. Mhando dzakasiyana dzeVIV dzinogona kuva modular dzakabatanidzwa kudzora VIP se zvinodiwa.VIV inosanganiswa neVIP prefabrication mugadziri, pasina pane-saiti Insulated kurapwa.Iyo chisimbiso unit yeVIV inogona kutsiviwa nyore.(HL inogamuchira cryogenic valve brand yakasarudzwa nevatengi, uye vogadzira vacuum insulated mavharuvhu neHL. Mamwe mabhurawuti nemamodhi emavharuvhu anogona kusakwanisa kuitwa vacuum insulated mavharuvhu.)

6.Kuchena, kana pane zvimwe zvinodiwa zvemukati chubhu pamusoro pehutsanana.Zvinokurudzirwa kuti vatengi vasarudze BA kana EP Stainless simbi pombi seVIP yemukati mapaipi kuti vawedzere kuderedza kupera kwesimbi isina tsvina.

7.Vacuum Insulated Filter: Chenesa tsvina inogona kuitika uye mazaya echando kubva mutangi.

8.Pashure pemazuva mashoma kana kureba kuvharwa kana kuchengetedza, zvinonyanya kukosha kuti precool iyo VI Piping uye terminal midziyo isati yapinda cryogenic fluid, kuitira kuti udzivise ice slag mushure meiyo cryogenic liquid inopinda zvakananga VI Piping uye terminal michina.Precooling basa rinofanirwa kutariswa mukugadzira.Inopa kuchengetedzwa kuri nani kwemidziyo yekumisa uye VI Piping midziyo yekutsigira senge mavharuvhu.

9.Suit kune zvose Dynamic uye Static Vacuum Insulated (Flexible) Piping System.

10.Dynamic Vacuum Insulated (Flexible) Piping System: Inosanganisira VI Flexible Hoses uye / kana VI Pipe, Jumper Hoses, Vacuum Insulated Valve System, Phase Separators uye Dynamic Vacuum Pump System (kusanganisira vacuum pumps, solenoid valves uye nezvimwe zvinopisa. ).Hurefu hwe single VI Flexible Hose inogona kugadzirwa zvinoenderana nezvinodiwa nemushandisi.

11.Various Connection Types: Vacuum Bayonet Connection (VBC) Rudzi uye Welded Connection inogona kusarudzwa.Mhando yeVBC haidi pa-site insulated kurapwa.